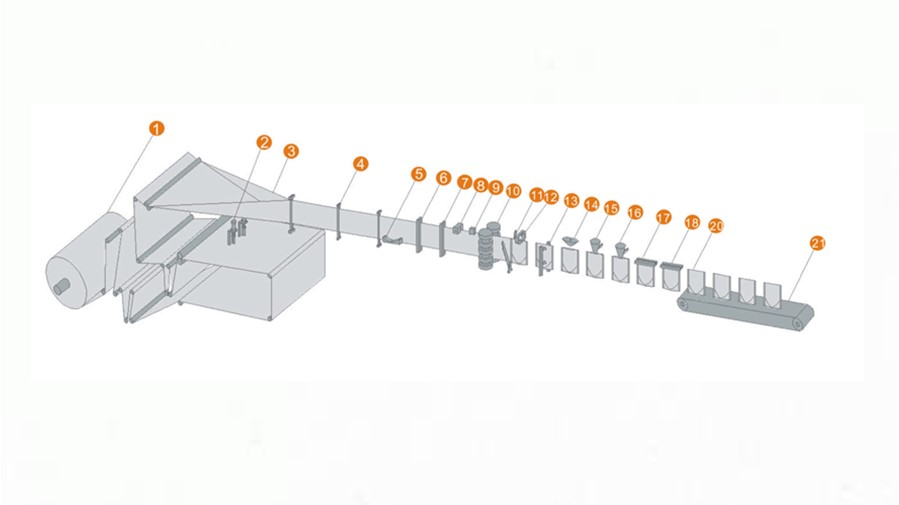

1.Film Unwind 2.Bottom Hole Punching 3.Bag Forming 4.Film Guide 5.Bottom Seal 6.Vertical Seal l 7.Vertical Seal II 8.Tear Notch 9.Photocell 10.Servo Advance 11.Cutting 12.Pouch Catching 13. Pouch Opening 14.Air Flushing 15.Filling I 16.Filling II 17.Top Seal I 18.Top Seal II 19.Finished Product 20.Outlet

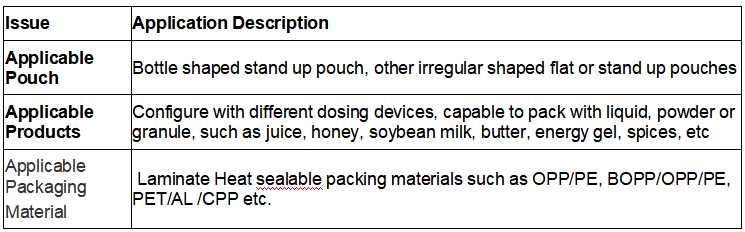

2. Applications of machine:

4. Features of machines:

Standard Features

· Apply carbon steel with plastic spraying structure covered by stainless steel 304, high strength

· Main movement beam and pouch holding bars applied with anodic oxidation and/or harden aluminum

· Stainless steel 304 for product touching parts

· PLC & Touch Screen HMI Control

· Intelligent PID temperature controller

· Servo motor for film pre-pulling and bottom hole punching

· Easy adjustment of the pouch length

· Twice top and vertical sealing processes

· Pouch vacuum and mechanical opening

· Vacuum system powered by vacuum pump with negative pressure tank

· Individual pressure tank for different compress air supplies

· Pouch not open completely, no fill and seal interlock

· Central lubrication system for punching device and other key mechanical parts

· Visual Protective Cover

· Cold Embossing type coding

·

Optional Features

·

Stainless steel 316 for product touching parts

·

Automatic film offset correction system

·

Tear notch Ribbon,

·

inkjet or laser coding

·

Cold sealing with chiller

·

Siemens Control System

·

5. Others:

Customization Philosophy

The product demonstrating may not perfectly meet your requirements, our philosophy is to customize your real need, To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

· Filling Materials

· Container to be filled, type and specification.

· Capacity requirement

· Automation requirement

· Protection requirement

· Other specific requirement

Selection Guide

Selection Guides are available for circulation, contact us to get products selection and customization support.

Statement

· The pictures demonstrating in this profile represent products of range, and subject to the newest or customized design

· Due to the huge number of documentation updating, the data indicated in this profile may not be updated timely, Please contact with our customer service for newest version.

· The features or functions appear in this profile subject to the additional description of quotation

FU-BO is your right choice

Domestic contact

No.7955, Jing Da road, Fengxian District, Shanghai, China

+86-18701769069

No.7955, Jing Da road, Fengxian District, Shanghai, China

No.7955, Jing Da road, Fengxian District, Shanghai, China +86-18701769069

+86-18701769069 tony@doypackmachine.com

tony@doypackmachine.com